Power Grid Equipment Monitoring

■ Partial discharge monitoring

Transformer casing, GIS combined electrical appliances, cable line joints, etc.

■ Fault gas monitoring in transformer oil

Including H2, CO, C2H2, C2H4, C2H6, CO2 and micro water, etc.

■ Monitoring of transformer core grounding current

■ Monitoring of zinc oxide arrester

■ Insulation monitoring of high-voltage capacitive equipment

Intelligent Monitoring and Fault Early Warning for Rotating Equipment

■ Comprehensive Perception

Monitoring Components:Motors, Fans, Lubricating Oil Systems, Regulating Systems

Collected Parameters:Include equipment status and operating condition data such as temperature, vibration, voltage, current, active power, flow rate, differential pressure, etc.

■ Fault Early Warning

Based on statistical and AI algorithm modeling, achieve early warning of faults.

■ Fault Diagnosis

Utilizing equipment mechanisms combined with AI modeling, intelligently diagnose both vibration and non-vibration faults.

■ Intelligent Operation and Maintenance

Based on real-time status evaluation and trend analysis, provide maintenance recommendations.

Monitoring of Temperature Field and Cold End Optimization in Air-cooled Towers

Intelligent monitoring systems for indirect cooling towers in thermal power plants aim to maximize the performance of cold-end equipment while ensuring the safe operation of the unit. This helps reduce energy consumption during winter operation, assisting enterprises in further energy conservation, emission reduction, cost reduction, and efficiency improvement.

■ Dedicated Temperature Sensor

A patented temperature sensor is used to directly measure the temperature of the finned tube wall.

■ Visualization of Temperature Field

Through a temperature acquisition system, the monitoring workstation dynamically displays the temperature field of the indirect cooling tower in a visual manner.

■ Frost Protection Warning

Combined with operational specifications and modeling analysis, the system monitors the entire process of water filling, operation, and withdrawal of the fan section. It automatically identifies and alerts temperature abnormalities.

■ Operational Guidance

Modeling of the air-cooling system is conducted, and based on the model analysis, guidance is provided for adjusting the return water temperature of the unit to improve vacuum and subsequently enhance the economic efficiency of the unit.

Intelligent Inspection System

Utilizing "high-definition video + robots + drones" to conduct visual and infrared inspections of equipment, combined with machine learning algorithms to automatically read meters and recognize abnormal states, significantly improving inspection efficiency and realizing intelligent and automated inspection operations. This system supports the construction of a modern equipment management system for enterprises.

■ Image preprocessing, feature extraction, sample management and other methods are used to develop and model the algorithm to improve the accuracy of model recognition.

■ Providing comprehensive work plans through preset inspection routes. In case of issues, it promptly alerts management personnel for handling and dispatching. Combined with maps and data, it can grasp the distribution of hidden hazards, adjust the inspection intensity of different areas, and enable real-time grasp of work priorities to prevent hidden hazards.

■ The intelligent inspection system can automatically generate inspection daily/monthly reports, hidden hazard type tables, trend analysis, and other content, effectively reducing the workload of manually collating reports for operational management personnel. It supports multiple viewing methods and can be displayed on both PC and mobile devices, providing managers with real-time and efficient access to information.

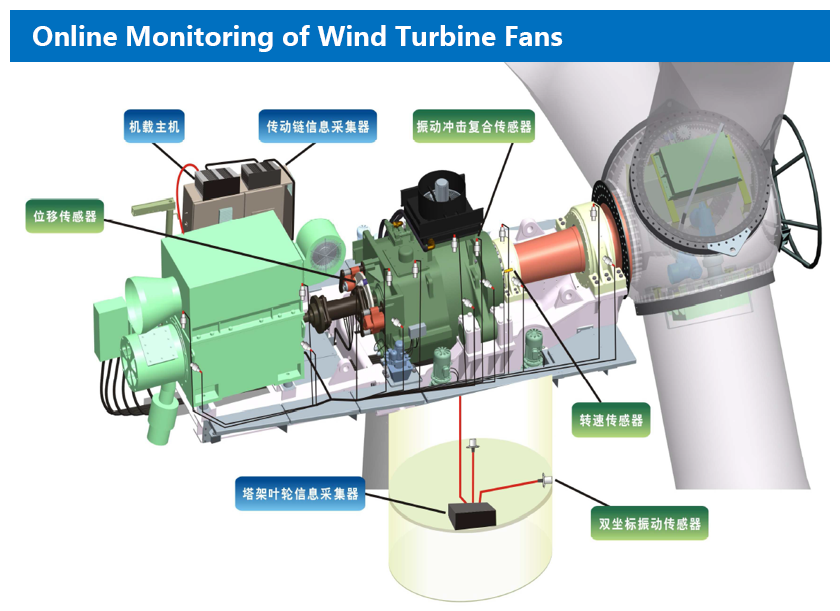

Wind Turbine Equipment Monitoring

Utilizing sensors to collect signals such as sound, vibration, and preload force from key components. Extracting status characteristics through digital filtering and time-frequency analysis techniques, and utilizing artificial intelligence technologies such as multi-modal modeling for real-time status monitoring and early fault warning.

■ Monitoring of Main Drive Train (Main Shaft, Gearbox, Generator)

■ Blade Monitoring

■ Tower Monitoring

■ Bolt Monitoring

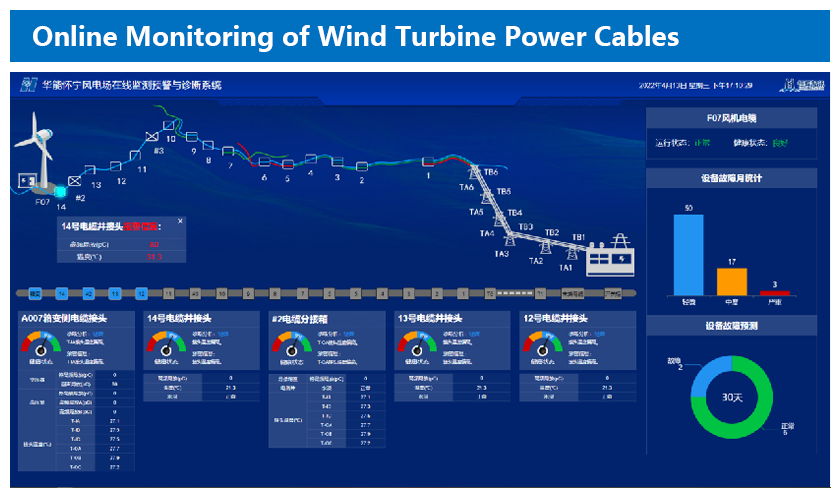

Real-time monitoring and early fault warning of cable line conditions are achieved by collecting data such as cable joint temperature, partial discharge, fault traveling waves, and circuit breaker contact clamping force.

■ Monitoring of Box Transformer ■ Monitoring of Overhead Cable

■ Monitoring of Cable Vault ■ Monitoring of Switchgear

■ Monitoring of Splice Box ■ Monitoring of Circuit Breaker

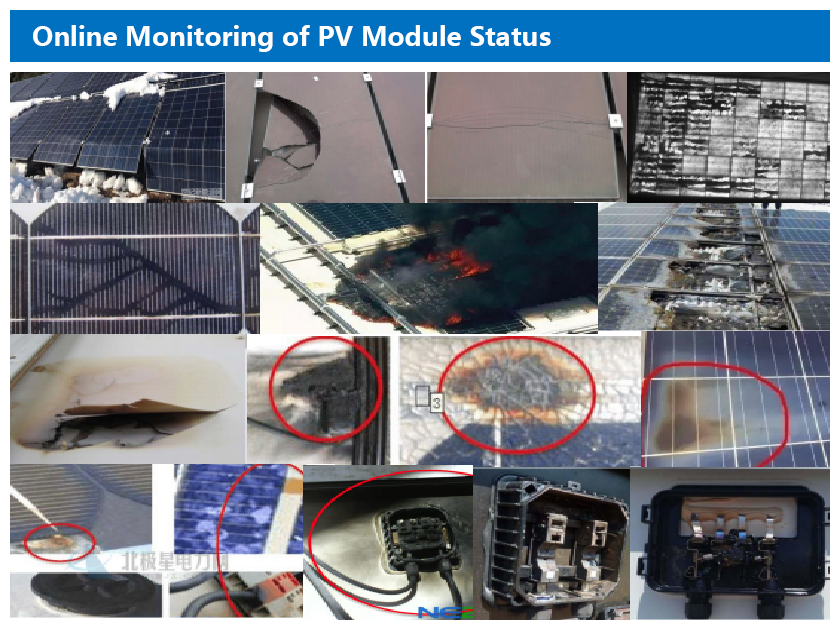

PV Equipment Monitoring

PV modules are the core components of photovoltaic power stations. A fault diagnosis and early warning system based on PV module status monitoring can effectively improve the reliability and safety of photovoltaic power generation.

A status monitoring system composed of sensors, field data collectors, data transmission modules, main station data processing servers, and back-end intelligent monitoring software is used. It monitors parameters such as output voltage, current, temperature, and water immersion of PV modules in real time. It also performs intelligent diagnosis of faults and can provide a visual display of fault diagnosis results.

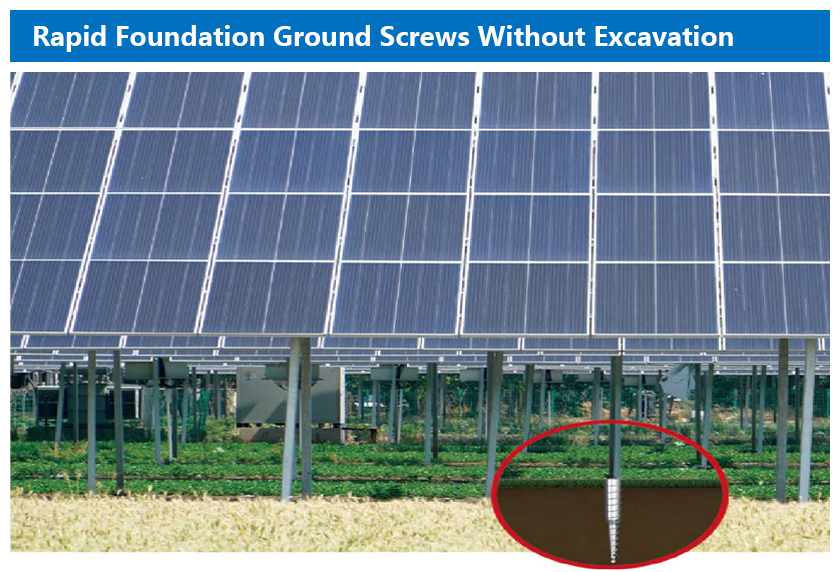

Ground screws can be used for the installation of all types of ground-mounted solar photovoltaic foundations. They are produced using high-quality steel and adhere to the latest or revised reference standards, with a yield strength of 235MPa to 600MPa. The average thickness of the galvanized coating on the ground screws is 60 to 80μm.

The ground screw products are produced through four processes, incorporating the latest standards and production techniques. Different models are available, and customization is also possible. This ensures reliable product quality, convenient installation, and long-lasting durability.